Thermoelectric generation – from temperature differences to electrical energy

The way of producing electricity utilizing temperature differences (Seebeck effect) or vice versa utilizing electricity for producing temperature differences (Peltier effect) was discovered already the 1800’s. Probably due to its relatively poor efficiency this phenomenon has still only found niche applications for energy production. However, the increasing demand for ways of producing clean energy and the fast development of material science and nanotechnology (e.g. thin film coating methods) has seen a new boom of research into these devices. In an ongoing project, Jamk University of Applied Sciences and several energy sector companies from the Northern Central Finland are aiming to bring the results of recent research and the possibilities of TE generation visible for the public and companies. This will be realized e.g., by arranging Living Lab demonstrations with existing TE devices in industrial and market environments. The main part of the funding for the project comes from the European Regional Development Fund

A sidestep for space exploration

In the vacuum of space no one can here you scream! However, there is something you can utilize for TE devices readily available, low temperatures. High temperatures are scarcer in space if you do not happen to be e.g., near a star. So, to utilize TE for power you need a source of heat. NASAs’ space probes and Mars rovers utilize radioactivity from plutonium dioxide for this purpose. These systems called Radioisotope Thermoelectric Generators (RTGs) provide a more efficient and compact power source compared to solar panels. The systems provide uninterrupted power for rovers during Martian dust storms which may last for weeks and are a big problem for solar panels. But back to earthly things.

Material junctions

Thermoelectric effect was first observed in junctions of metals. The power generation efficiency in metal junctions is poor, however “thermocouples” manufactured from metals and metal alloys are widely used for temperature measurement. Most current research on materials for TE generation concentrates on the junctions of semiconductors which have a more pronounced TE effect. Semiconductor junctions are prepared from two different types of semiconductors namely n -type and p -type, with majority charge carriers being negatively and positively charged, respectively.

Figure of merit and material properties

The efficiency of TE materials is evaluated by a scale of the so-called figure-of-merit. The figure-of merit depends on the electrical and thermal conductivities of the material and something called a Seebeck coefficient. In theory, it sounds very easy to make a good TE material. You need material with high electrical conductivity, low thermal conductivity and high Seebeck coefficient. However, these material properties have complex dependencies, and this makes the development of new materials, in practice, very cumbersome. E.g., thermal conductivity of a material typically has contributions from electrons and lattice vibrations. Thus, by increasing electrical conductivity you also increase the electronic thermal conductivity. So, to simultaneously increase electrical and decrease thermal conductivity, the way to go is to try to prevent the progress of the thermal conducting lattice vibrations through the material. This can be done e.g., by adding impurities by way of atoms, molecules, and thin films layers.

Thin film thermoelectrics

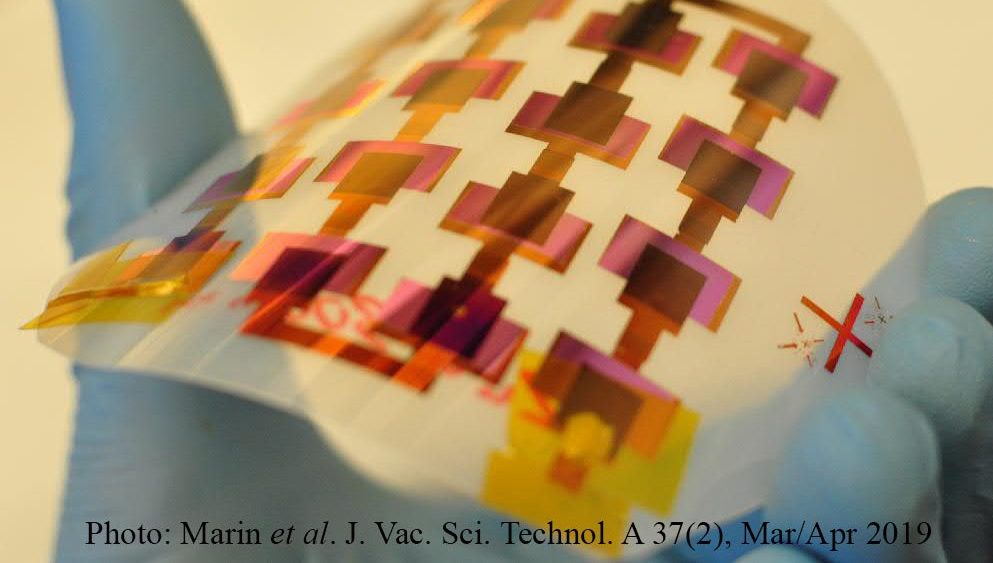

Thin films are appealing for both thermoelectric cooling and heating applications. Thin film coating methods, especially ALD (Atomic Layer Deposition) are widely used by the electronic industry. Being the most controlled way of preparing uniform, and the superior method for preparing conformal thin films, ALD is the coating method of choice when preparing nanostructures. With ALD and by combining ALD with its’ sister method MLD (Molecular Layer Deposition) controlled nanolaminate and superlattice structures with tailored thermal and electronic properties can be prepared.

Groundbreaking research on nanostructured thin film thermoelectrics has been done by Academy Professor Maarit Karppinens’ group at Aalto University. However, the field of research of thermoelectric thin films is still very young and very few efforts have been made to fabricate actual TE modules. One limiting factor has been the scarcity of p-type thin film materials.

Waste heat recovery and power to the people

Currently the efficiency of the available TE devices at the temperatures readily available in our everyday environment are still insufficient for the general breakthrough of the technology. However, TE materials are intensely studied for waste heat recovery from homes, industry, and transport systems and will most likely be an integral part of the tool pack of clean energy solutions sooner than later.

A field of applications were ALD thin films have a lot of potential are wearable systems converting body heat to electricity to power medical sensors or other small portable devices. The development of R2R ALD systems allows for the large-scale deposition of high-quality, uniform, and conformal thin films on flexible and nanostructured surfaces.

Author: Esa Alakoski, Project Engineer, PhD, Läsä -project, CAMS, ALD CoCampus, JAMK University of Applied Sciences