Killing the killers – improved anti-microbial surfaces by ALD?

The Sami-Samu project

In a soon to be finished project VTT – Technical Research Centre of Finland, Jamk University of Applied Sciences and Central Finland Central Hospital joined forces in search of new ways of using wood-based antimicrobial substances in hospital environments. The target of the Sami-Samu project was to improve the antimicrobial properties of materials and surfaces and furthermore to reduce the use of oil-based polymers in hospitals. The project partners included nine companies, and the bulk of the funding came from the EU via European Regional Development Fund.

Bug resistant materials and surfaces

Materials interact with their environment mainly via their surfaces. Thus, a way of making a material more resistant to bacterial or viral attack is to tailor its surface properties e.g. by coating it with a thin layer of an antimicrobial material.

Typical antimicrobial materials can be metals, such as Copper (Cu) or Silver (Ag), metal oxides such as Zinc oxide (ZnO), Titanium dioxide (TiO2) or Tungsten oxide (WO3) or several types of synthetic or natural polymers. As different materials have different ways of action, combinations and hybrids of different materials may be more efficient against microbes compared to a one material.

There is wide range of commercially available methods for depositing antimicrobial coatings, each of them having pros and cons. However, currently the coating method that is seeing a worldwide boom of research and development and a completely new range of applications is Atomic Layer Deposition (ALD).

ALD – The long march to success

Doctor Tuomo Suntola invented ALD method in Finland already in the 1970’s. Even in the 90’ there was a common consensus in the industrial circles of ALD being a too cumbersome and difficult method to find any commercial success. The current ALD research boom, however, began a little over ten years ago with the methods wide acceptance by the electronics industry for the deposition of dielectric layers in transistors. The commercial value of Suntolas work was finally acknowledged in 2018, when he was awarded the 1M€ Millenium technology prize.

ALD – The coating method that loves fibers

ALD is the most controlled of thin film deposition methods and is based on sequential self-limiting chemical reactions. This control is the magic behind the exceptional properties of ALD coatings, namely unrivaled conformity, uniformity, and atomic scale thickness control. Furthermore, ALD films do not suffer from pinhole problems typical to films prepared with many common commercial deposition methods. These benefits make ALD the method of choice for producing coatings on fiber-based materials. ALD coatings give the fibers an overall, smooth and dense coverage.

High tech from the Finnish forests – ALD precursors from wood extracts?

Several studies have shown that lignin and several other of the tens of chemical compounds in wood extracts are antibacterial. Cocktail of these constituent makes e.g. wooden kitchen utensils more hygienic than plastic ones. Clearly, such a cocktail is not suitable as source material, precursor, for ALD. Controlled ALD reactions require well-defined chemical compounds. However, there nothing to prevent the use of an antibacterial wood extract compound as a precursor if it fulfills the essential requirement for a precursor. This requirement is: sufficient vapor pressure, stability and reactivity at the deposition temperature. Furthermore, the compound should not react with itself. Research into such wood-based compounds might be one avenue towards the development of high benefit products from the Finnish forests.

Meet the main culprits of infection; bacteria and viruses

Bacteria and viruses cause most human infections and deceases. Although the symptoms caused by these microbes are often similar, bacteria and viruses are very different entities. There is a huge size difference, the size of bacteria is in the micron scale, and the sizes of viruses range from a minimum of tens of nanometers to maximum of a couple of hundred nanometers. Bacteria are single-celled organisms that reproduce, as cells do, by binary fission. Viruses on the other hand are not considered to be living things. All things alive are composed of cells. Viruses only contain the genetic material of cells, DNA and RNA. These bastards have a sneaky way of reproduction; viruses invade living cells and harness the cells to make copies of themselves. The process continues by the death of the invaded cell and the release of a new band of these villains.

Both bacteria and viruses are prone to mutations in their genetic material. These mutations may lead to the development of e.g. bacterial strains resistant to antibiotics. This happens when antibiotics kill the common strains and leave the mutated resistant strains to multiply. However, to end on a positive note, it is not evolutionarily beneficial for the germ to kill the host. So, there is often a tendency for microbial strains to become less virulent over time.

Fighting back

Prophylactics that work on bacteria do not necessarily work on viruses and vice versa. An example of this is that antibiotics do not kill viruses. Tailoring a ”Broad-spectrum antimicrobial” surface requires a thorough understanding of the physical and chemical structure of both bacteria and viruses and a multidisciplinary approach.

Common hospital curtains contain silver deposits as an antibacterial agent. Copper has a similar antibacterial properties and way of action like silver. During the last winter both an antimicrobial tape containing a cocktail of copper and silver and wood-based extracts have been tested in the door handles at JAMK. Combinations of such substances and adding metal oxides would be a way to increase the anti-bacterial efficiency of surfaces even more.

Attack on all fronts on every nook and cranny

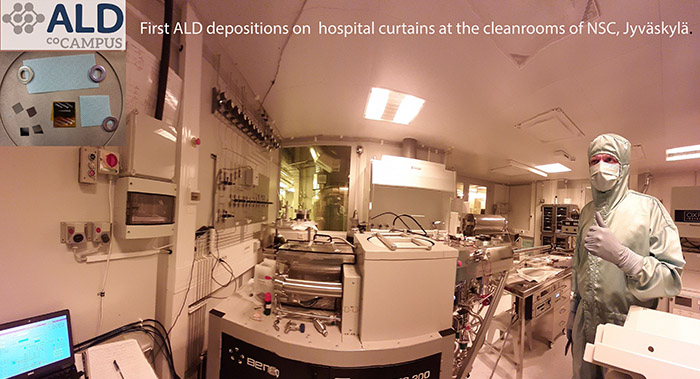

Metal-oxides have a different anti-bacterial way of action compared to metals. Especially under UV irradiation TiO2 and ZnO show broad-spectrum antimicrobial properties. Furthermore, these oxides have many other beneficial properties, they are chemically stable, non-toxic, and fire resistant. Metal oxide ALD coating may also e.g. protect a plastic substrate materials from UV induced degradation. A well-learned lesson from WW1 is that well-organized defenders can ward-off full frontal attack of heavy forces. Attacking on several fronts at once is a better way to get the job done. As there are many well-behaving ALD process readily available for TiO2 and ZnO these materials have a lot of potential as coatings to increase the antimicrobial efficiency of surfaces. Furthermore, roll to roll ALD coating systems, such as pilot scale Beneq WCS 500 at Jamk, can be utilized for the deposition of these bug-killing compounds on fabrics and fiber-based materials.

Writer: Esa Alakoski, Project Engineer, PhD, SamiSamu -project, CAMS, ALD CoCampus, JAMK University of Applied Sciences